New location and a larger, modern factory

New location and a larger, modern factory

At the end of 2018, Ekoplast’s new head office was opened and a new factory with an area of 13,000 m2 in Kokotów, near Kraków. The investment in a modern machine park includes, among other things, new machines for the innovative technology of perfect V-Perfect weld connection.

On the premises of the new Ekoplast investment in Kokotowo, a covered warehouse was also located, in which the windows and doors manufactured in our factory are stored in optimal conditions for this type of products.

V-Perfect - PVC windows have never been so perfect

V-Perfect - Pvc windows have never been so perfect

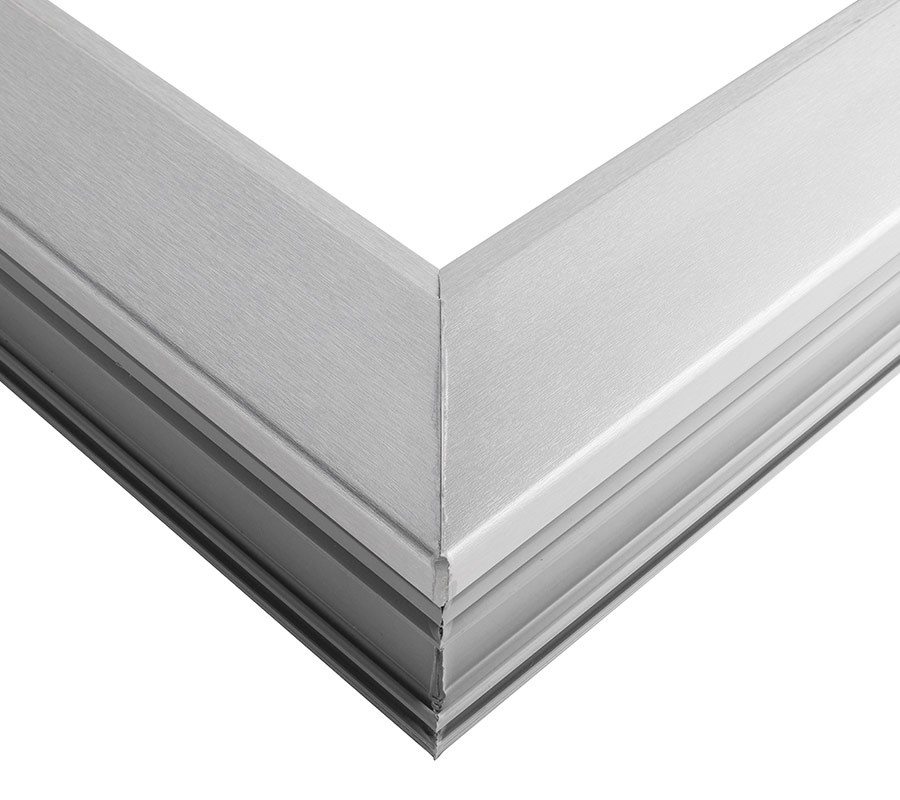

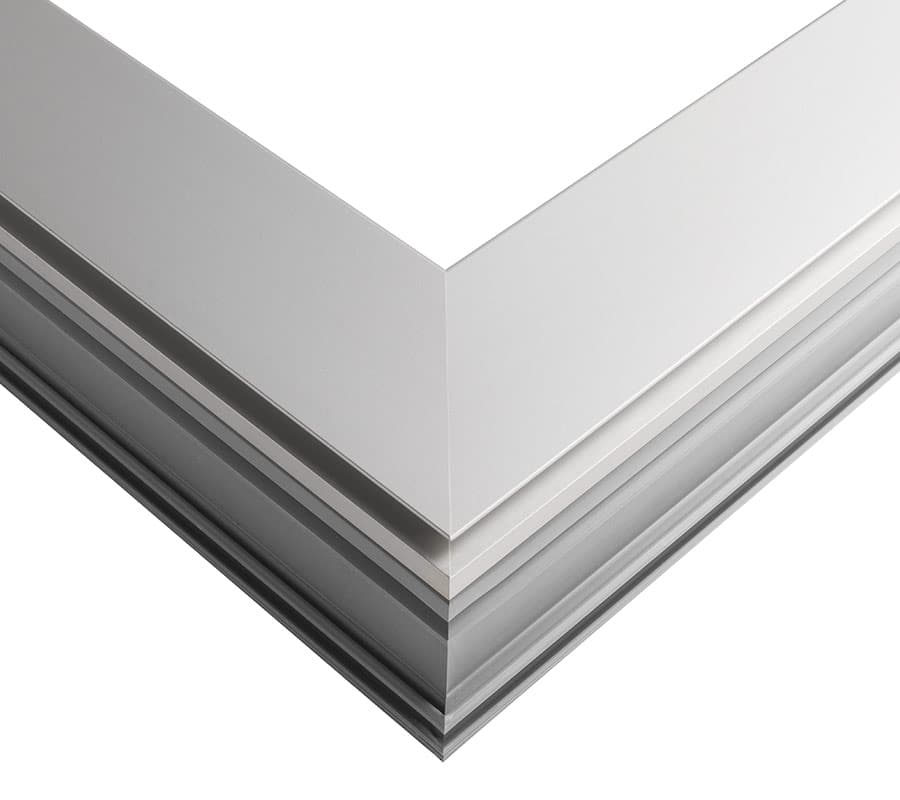

The application of V-Perfect technology guarantees the highest quality, durability and aesthetics of PVC window angles. The aspect of these will be appreciated by customers who expect higher level services, prestigious investment promoters where every single detail is of enormous importance, as well as architects looking for solutions that give a wide maneuvering fields. Everyone will be able to appreciate the technological properties of the V-Perfect technology!

V-Perfect is a new welding technology that allows a perfect joining of the profile angles of PVC windows. To understand its advantages, it is advisable to compare profiles joined by the application of this method with those which are welded in another way. The traditional method sometimes requires tedious manual processing that does not give satisfactory effects to demanding customers, both as regards the aesthetics of execution and durability. Angles and profiles joined in the traditional way are subject to treatments such as milling or cleaning, or it is also very often used a technique of masking some traces with retouching pens. What also has a great impact on the aesthetics of the windows is also the fact that, in traditional models, the seal is welded to the profile. At the location of the weld is thus created a hardening which is impossible to remove completely, even after cleaning or painting.

Now, with the V-Perfect technique this type of treatment is no longer necessary. Thanks to V-Perfect you can achieve a much better effect in a short time. Almost unlimited possibilities of welding forms avoids the painting of traces after joining the elements, so that their appearance remains unchanged for a very long time.

V-Perfect technology allows profiles to be coated with other materials such as film or even wood or aluminum veneer, giving designers or architects greater freedom in the choice of window aesthetics. V-Perfect is a tried and tested solution that we apply recently in EkoPlast Kraków windows. Thanks to its application, we can offer you even more quality at a reasonable price.

V-Perfect is:

- welding perfection ensures an aesthetics never reached before by the PVC

- possibility of coating PVC profiles with the most noble materials such as wood, aluminum or other

- freedom of design

- perfect appearance regardless of passing time

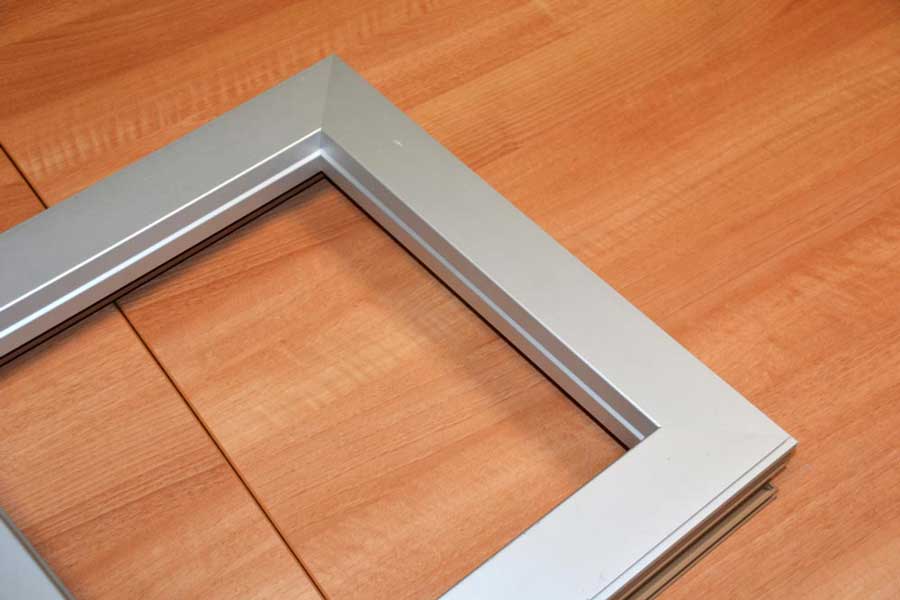

Comparison of angles made with traditional technology (left) and with V-Perfect (right).

Innovative technology 'Foam Inside'

Innovative technology ‘Foam Inside’

Energy efficiency

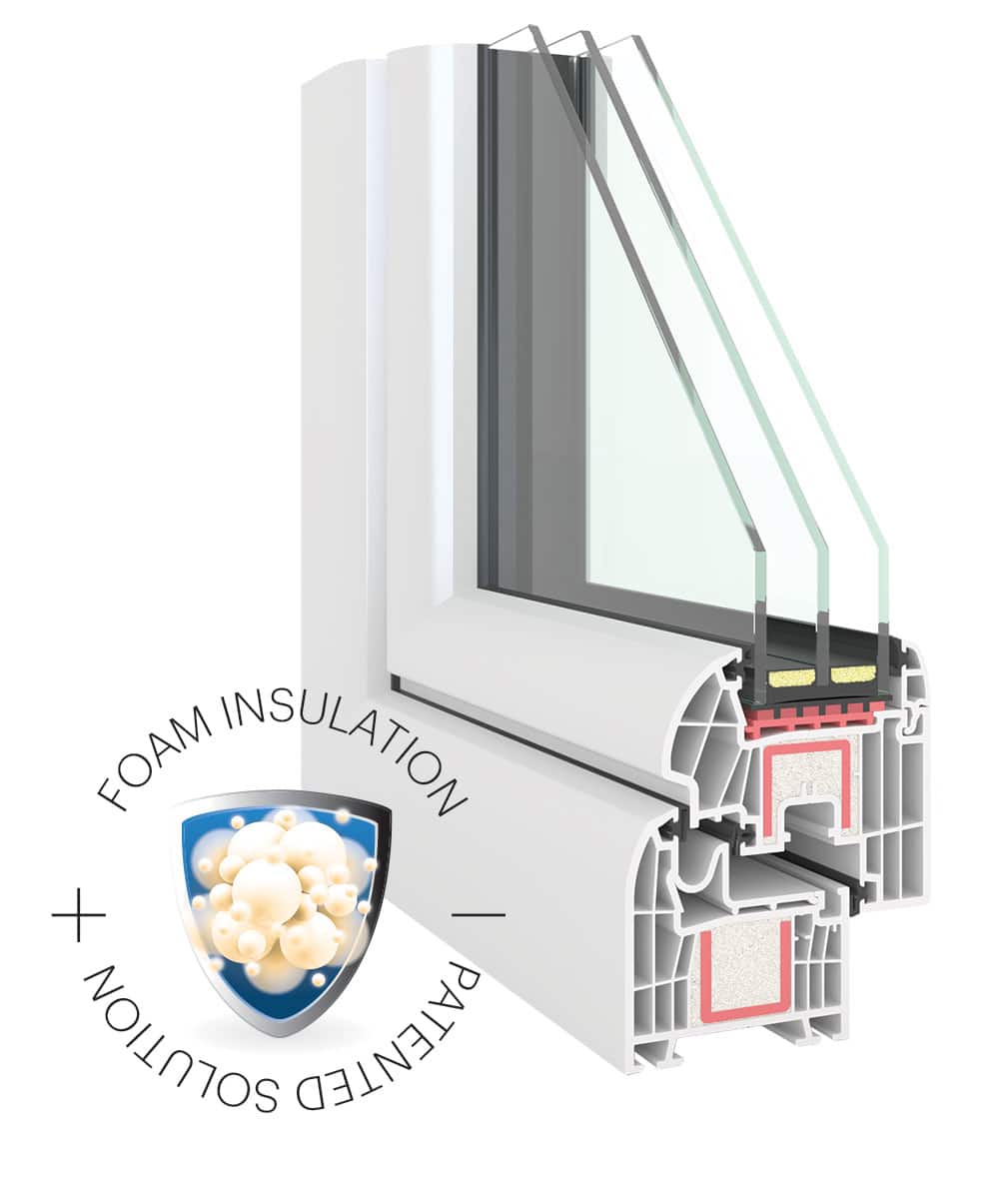

Energy efficiency is one of the key parameters when designing new buildings and renovating old ones. As you know, windows are one of the weakest points of the entire wall. Applying only appropriate glazing, which have a positive impact on the heat balance of the building, we will see that windows can often reduce the need for energy needed to heat the room. Window profiles are the weakest link in energy efficiency.

The direction in which the development of window systems has been indisputably for many years is to reduce the heat transfer coefficient of profiles. It is a pan-European trend, stimulated in many countries by appropriate regulations in this area, in others it is a result of strong competition. Many window companies try to bring more and more new solutions to the market, the effect of which is the emergence of messages about increasingly hot profiles. Of course, improving certain parameters is now possible thanks to the use of better components with higher properties

Innovative technology of filling profiles

Minimizing heat loss has become one of Ekoplast’s main goals. Many years of research, tests and improvements have been successful in the form of a significant reduction in the heat transfer coefficient of window profiles.

Based on preliminary work and research, the team decided to implement an innovative technology of filling the profiles with additional insulation material, a special polyurethane foam. The technology has been developed with the aim of creating PVC windows characterized by excellent thermal insulation values, reducing economic and environmental costs. The polyurethane foam allows the internal profiles to be filled with additional insulating material after the final sealing of frames or sashes. Properly applied foam cools and increases its volume, filling the window frame space to the corners, allowing significant improvement in the thermal properties of the windows up to 30%.

Thanks to the optimization of such factors as the filling time of 1mb profile, foam adhesion, temperature and composition of components, air pressure, the number and location of vent holes, or the place of foam application, we achieved an improvement of UW to 30%, depending on the size of the window.